The use of filler masterbatch, particularly PP filler, has increased dramatically over the last decade. PP woven is a major contributor to PP calcium carbonate filler consumption. So, how does the woven sector benefit from PP filler? Let us find out in this article!

1. Definition of PP filler masterbatch for PP woven bags

Polypropylene (PP) has long been known for its superior mechanical properties. Thus, it is used in a variety of applications, including laminated film, household appliance manufacturing, and the non-woven and specially woven industries. However, the use of fossil materials is costly and uncertain, which may harm the continued existence of plastic enterprises. This is why PP calcium carbonate filler is used to produce the production of PP woven.

PP calcium carbonate filler (also known as PP filler masterbatch) is made up of PP resin, calcium carbonate (CaCO3), and other specific additives. A suitable PP filler loading rate will be determined based on the woven requirements (typically between 15% and 40%). The addition of some common additives (dispersion agent, processing aid, etc.) is meant to improve the performance of the final combination during the manufacturing process.

2. Benefits of using PP filler masterbatch for PP woven bags

2.1. Using PP filler masterbatch for PP woven bags lowers production cost

CaCO3, the main component of PP calcium carbonate filler, is what makes it so effective. Taking up to 70% of the total weight reduces the amount of PP resin required, significantly lowering production costs. Furthermore, due to its natural availability, CaCO3 is far more reasonable and stable than PP resin. Thus, using this material can effectively reduce production costs while minimizing the negative effects of market fluctuations.

2.2. Benefit of enhancing mechanical properties

Another advantage of PP filler is its ability to improve PP woven mechanical properties like flexural strength, impact strength, and tear resistance. Because PP resin is also a component of PP calcium carbonate filler, it is easily compatible with current plastic combinations, resulting in faster dispersion on the woven bag surface. In addition, PP filler improves the shape of woven yarn by increasing stability during the manufacturing process.

2.3. Increase productivity with PP filler masterbatch for PP woven bags

Because of calcium carbonate's high thermal conductivity, PP filler masterbatch can reduce the time required for each product cycle while also saving a significant amount of energy, thereby increasing productivity and efficiency.

3. PP filler masterbatch from StarPoly Vietnam

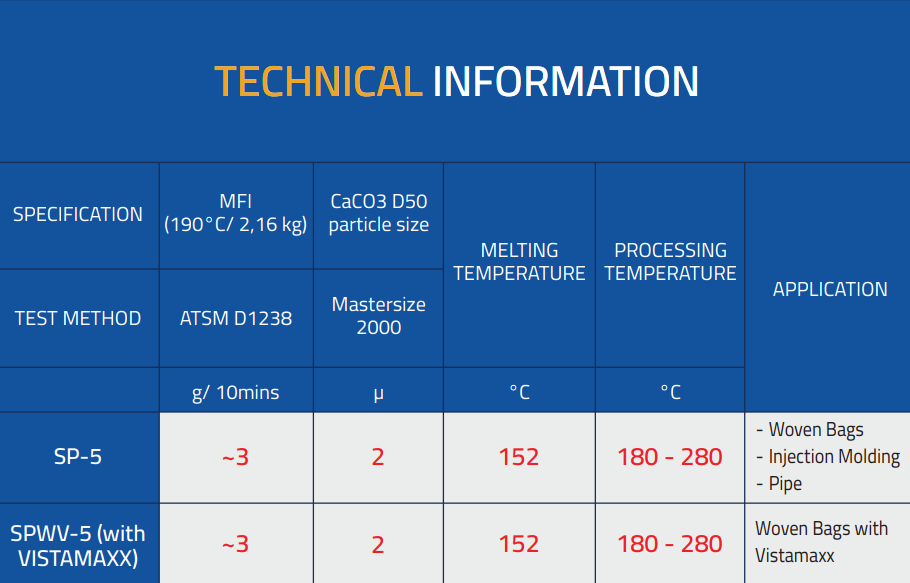

Product information:

We also have grades for high-speed machines and customize grades depending on the production parameters of clients.

To place an order and get the free sample, please contact us now!

Alison Taylor (Ms)- StarPoly’s Technical Sales Executive

WhatsApp: +84 82 766 1263

Email: Alison@starpoly.vn/ sales6.starpoly@gmail.com

Skype: Sales6 StarPoly (Ms Alison)